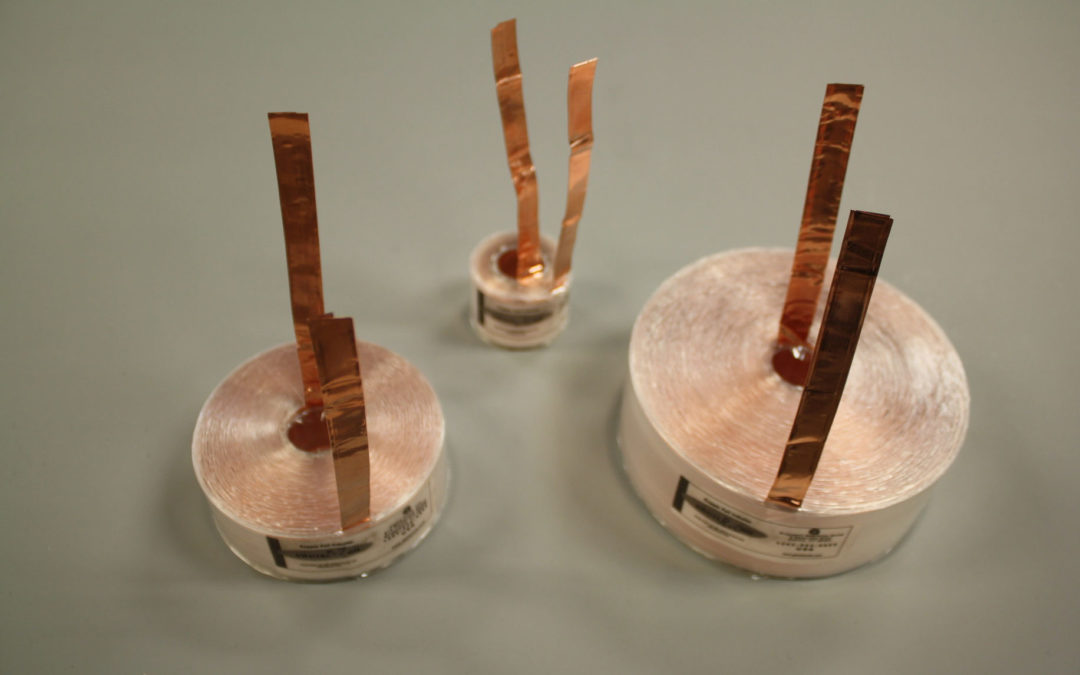

Foil Inductors

Overview

High-technology laminating makes it possible to manufacture inductors from high purity copper or silver foil wound onto a Lexan polycarbonate tube. Foil inductors are mounted by means of a single polycarbonate screw through the central bore, or a silicone elastomer, or a hot-melt adhesive.

Foil inductors have obvious advantages over wire-wound inductors in terms of improved electrical and sonic characteristics. This important new development has much to contribute to the design of state-of-the art loudspeaker crossover networks.

Leads:

0.010 x 0.321 inch

copper or silver

Conductors:

99.99% pure copper

or silver foil

Dielectric:

0.0015 inch thick

polypropylene film

Gauges:

12,14, and 16 AWG

Inductance Tolerance:

+/- 2.5%

Inductance Reactance:

Flat from 5Hz to 50kHz

- Negligible skin effect below 100 kHz many orders of magnitude below conventional wire-wound types.

- High winding tension and vacuum fusing of faces provides high dimensional stability, effectively locking the conductors in place. Wire-wound inductors, which allow relative motion of conductors due to electromagnetic forces, will exhibit FM distortion by the process of reactance modulation.

- Flat inductive reactance from 5 Hz to 50 kHz.

- No saturation distortion due to air-core design.

- Inductors contain no magnetic materials.

- Reduced power loss.

- Highest space factor (ratio of conductor cross area to total cross-section) means lower DC resistance within comparable dimensions. Negligible power loss due to skin-effect.

- Extremely low stored charge.

- Cool operation even during prolonged high output power operation.

- The high space factor and winding density results in improved heat dissipation.

Since we introduced our Air Core Inductors in 1997 they have become standard fixtures in many of the worlds finest speakers, and thousand of audiophiles have improved their sound by personally upgrading their crossover circuits with our products.

Goertz developed the combination of high grade OFC copper with polypropylene film as the dielectric, wound onto a non-hygroscopic core able to endure the sometimes high working temperature without long term shrinkage. We knew that a loose center will allow relative motion of layers due to electromagnetic forces, leading to FM distortion, so we chose LEXAN™ a high strength, super stable engineering resin for our cores.

We also developed the vacuum fusing process in order to further preserve the long-term integrity of our inductors..

Research has no limits, so throughout the years we have worked on improving our product and proprietary manufacturing equipment. As a result we are now winding our inductors even tighter, to closer tolerances and at increased productivity. Inductors are calibrated within 2.5% of nominal, wound with superior tightness and fused at both ends, hermetically protecting the conductor (be it copper or fine silver) against tarnishing with time.

We have also increased the number of standard values.

Reach Us

Contact Us for Information and Sales

6 Waterview Drive, Shelton, CT 06484